Services

3D printing

Fused Deposition Modeling (FDM)

Fused Deposition Modeling (FDM), also known as Fused Filament Fabrication (FFF), is a widely used 3D printing technique. This method involves the precise application of material layer by layer to create three-dimensional objects. In FDM, a solid thermoplastic filament placed on a spool in a 3D printer is fed into an extruder. The extruder heats and melts the filament, and the molten material is then precisely deposited onto the build platform. By successive layering, the final object takes shape.

3D printing

Digital Light Processing (DLP)

Digital Light Processing (DLP) is a sophisticated 3D printing technique that utilizes a digital light projector to cure photopolymer resin layer by layer. In DLP, a vat filled with liquid photopolymer resin is exposed to light patterns projected by a digital projector. These light patterns selectively harden the resin, forming a solid layer. The build platform then moves incrementally to allow new resin to flow over the cured layer, and the process repeats. This method ensures high precision and smooth surface finishes, making DLP ideal for detailed and intricate designs. By precisely controlling the light exposure, DLP produces high-quality 3D objects with fine resolution.

3D modeling

Professional 3D modeling

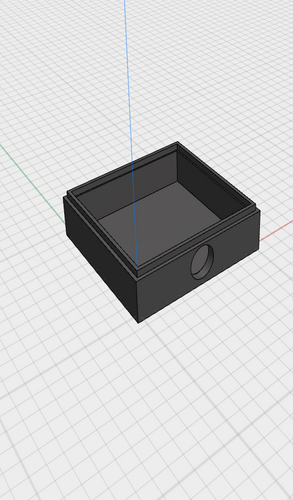

3D Modeling Service is an essential aspect of the 3D printing industry, involving the creation of digital representations of three-dimensional objects. This process begins with a concept, which is then brought to life using specialized software to design detailed 3D models. These digital models serve as the blueprint for physical objects, capturing intricate details and precise measurements. Skilled 3D modelers can transform sketches, technical drawings, or ideas into accurate, printable files. This service is crucial for customizing designs, prototyping, and ensuring the final product meets exact specifications before production.