Materials

FDM technology

| Print area | 256x256x256 mm | 350x350x350 mm |

| Resolution | 0,05 mm | 0,05 mm |

| Nozzle temperature | 300 °C | 300 °C |

| Heat bead temperature | 120 °C | 110 °C |

| Available materials | PLA, ABS, PETG, TPU 95A, ASA, HIPS, PA12,PC | PLA, ABS, PETG, PETG, ASA, HIPS |

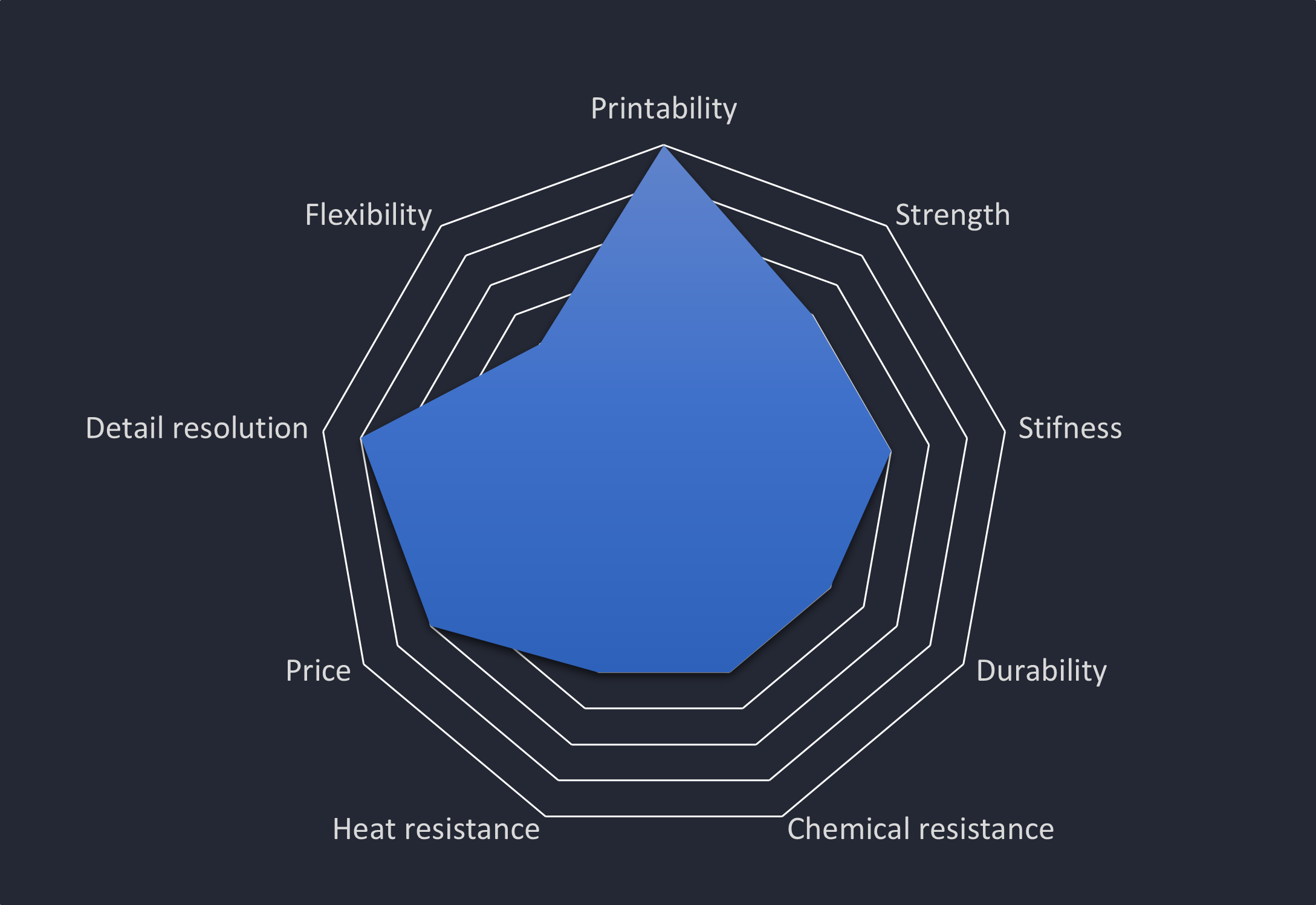

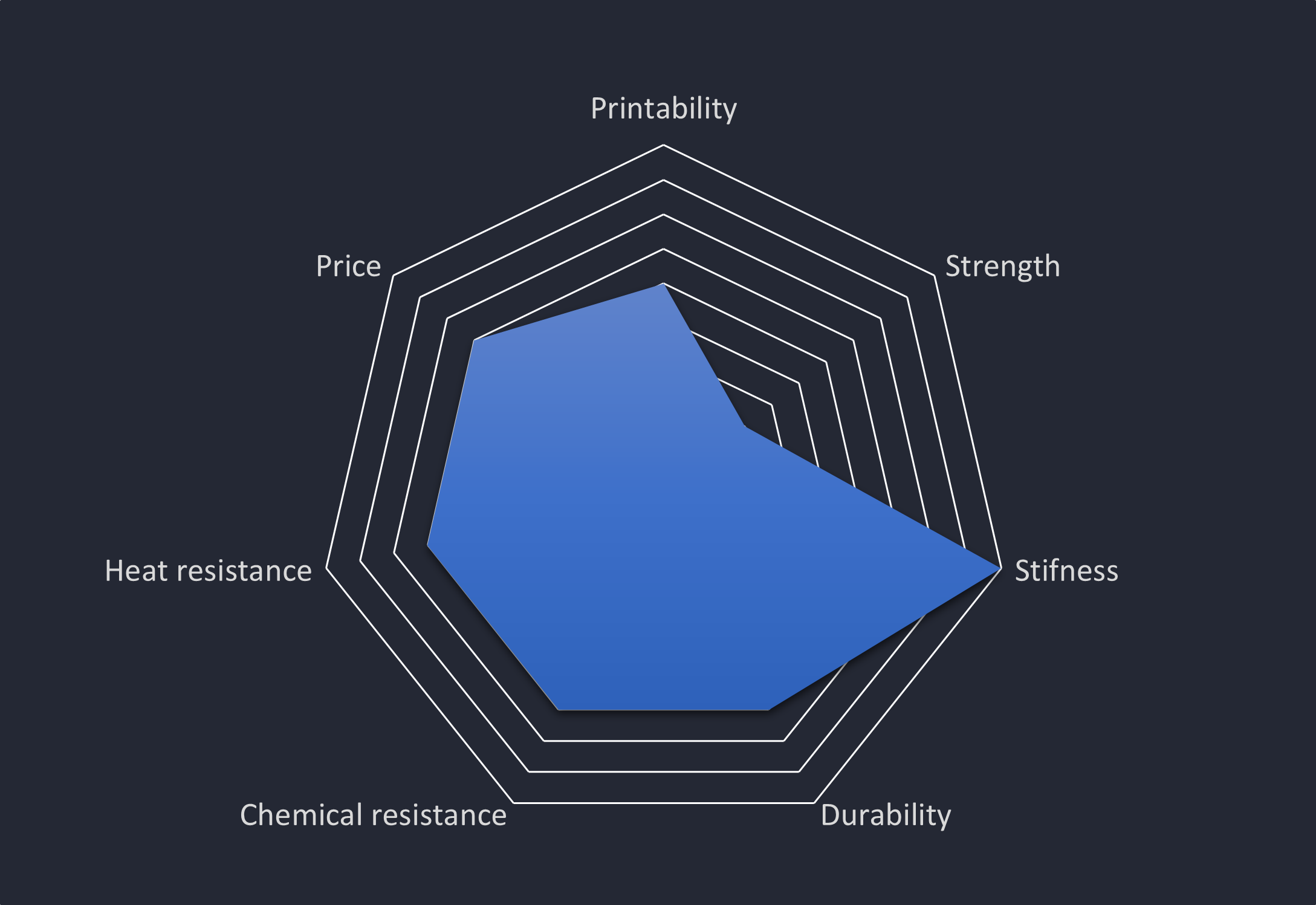

PLA

Polylactic acid (PLA) is a widely-used thermoplastic polymer for 3D printing due to its desirable properties. Derived from renewable sources like corn starch or sugarcane, PLA is eco-friendly. It offers ease of use with low printing temperatures, minimal warping, and excellent layer adhesion. PLA is also known for its biodegradability, which further enhances its sustainability.

PLA – Aero

This derivative of PLA is particularly well-suited for specialized applications like 3D printing of RC planes, thanks to its low density, lightweight nature, and impressive toughness with good impact resistance.

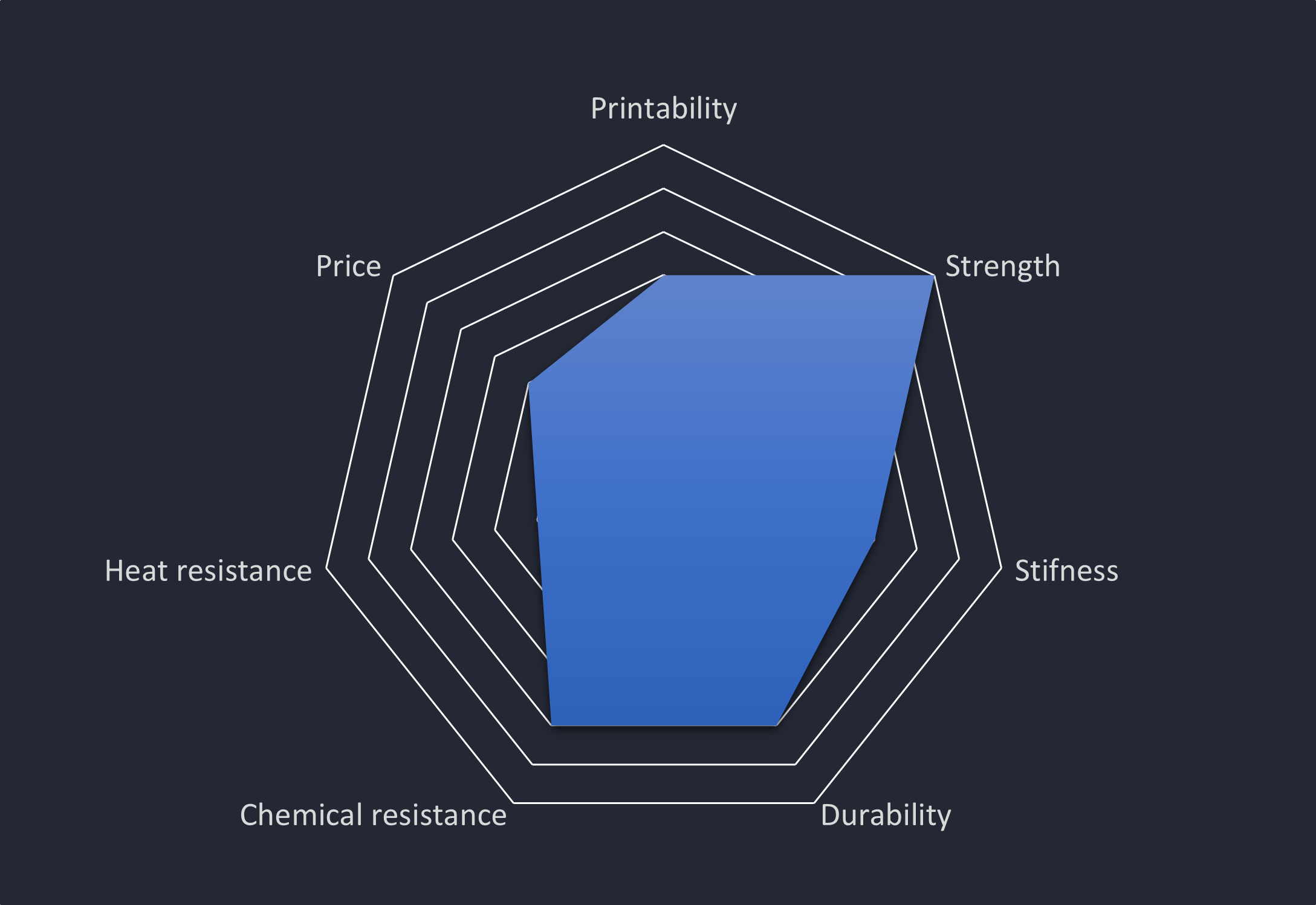

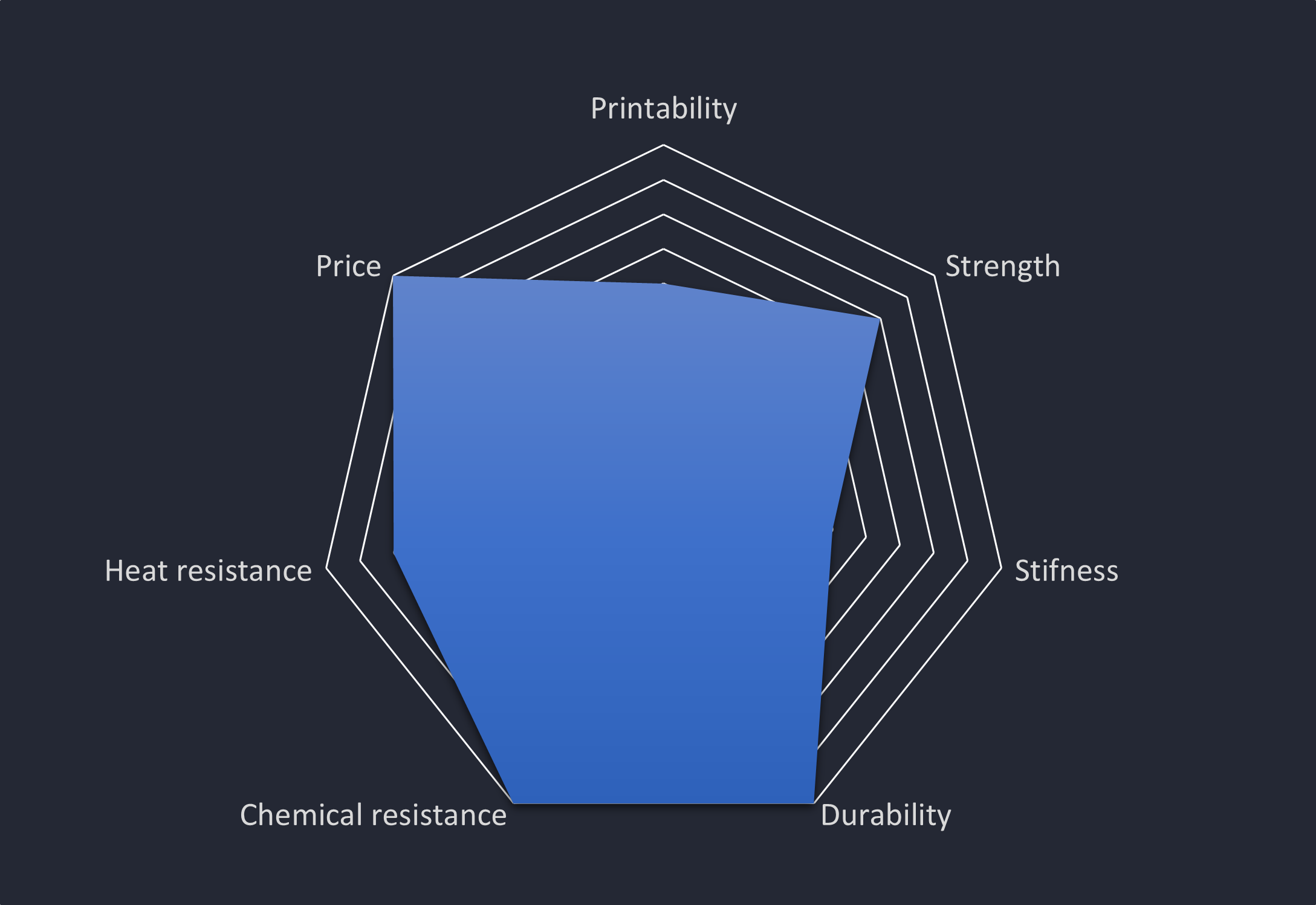

ABS

Acrylonitrile Butadiene Styrene (ABS) is a widely-used thermoplastic polymer in 3D printing, known for its unique set of properties. ABS is derived from petrochemical sources and is favored for its durability and strength. It exhibits a higher melting point than PLA, making it more suitable for functional parts and prototypes that require greater toughness and heat resistance. ABS is favored for applications where resilience, heat resistance, and mechanical strength are critical, making it a popular choice for engineering and automotive components. Additionally, PETG is available in a transparent variant, making it particularly suitable for applications that require optical clarity, such as medical devices, lighting components, or clear containers.

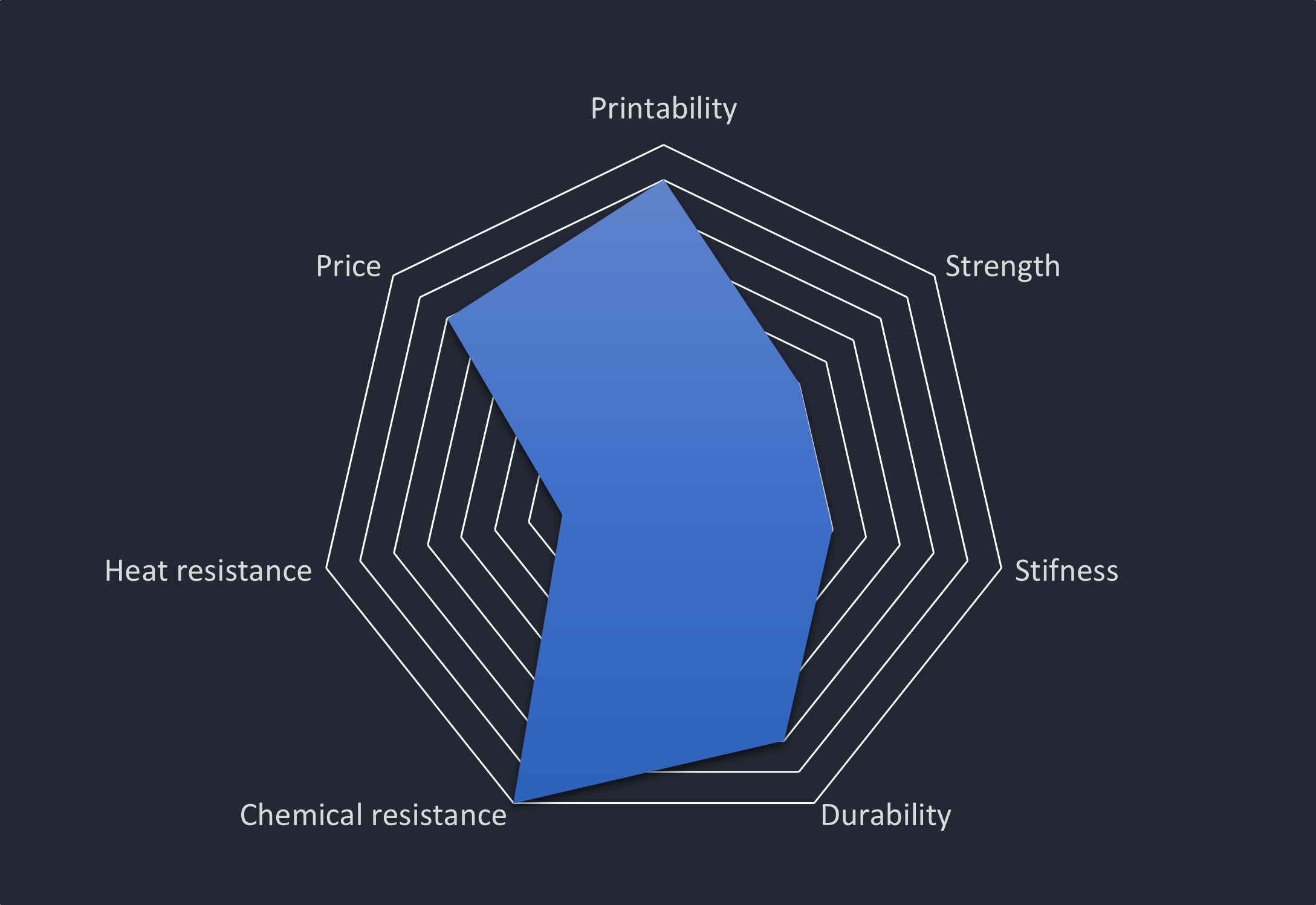

PETG

Polyethylene Terephthalate Glycol (PETG) is a versatile thermoplastic polymer widely utilized in 3D printing for its exceptional properties. Derived from PET, the same material used for plastic bottles, PETG offers a unique combination of strength and ease of use. PETG 3D prints are known for their excellent layer adhesion, durability, and resistance to impact and moisture. This material is a popular choice for functional parts, mechanical components, and containers, where a balance between strength and ease of printing is crucial. Additionally, PETG is available in a transparent variant, making it particularly suitable for applications that require optical clarity, such as medical devices, lighting components, or clear containers.

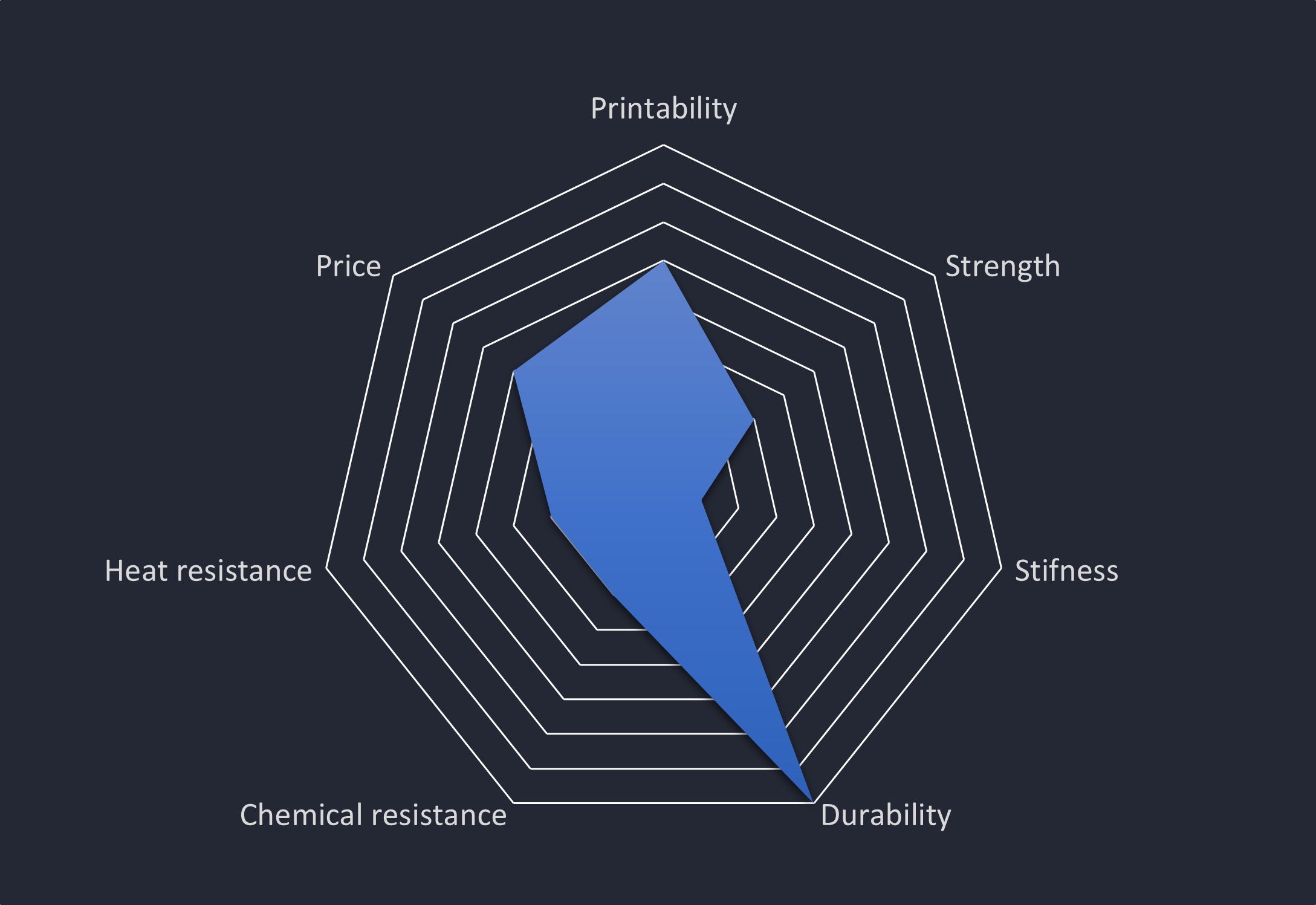

TPU 95A

Thermoplastic Polyurethane 95A (TPU95A) is a specialized elastomeric material known for its flexibility, resilience, and durability. It possesses a Shore hardness of 95A, making it relatively rigid while maintaining excellent elasticity. This material is highly resistant to abrasion, impact, and chemicals, making it ideal for applications requiring toughness and flexibility, such as custom gaskets, seals, or wearable items like shoe soles and phone cases.

ASA

Acrylonitrile Styrene Acrylate (ASA) is derived from ABS and is renowned for its excellent UV resistance, making it highly suitable for outdoor and long-term applications. It boasts exceptional toughness, heat resistance, and resistance to chemicals and weathering, ensuring that 3D printed ASA objects maintain their structural integrity over time. ASA is particularly valued for its ability to retain its color and mechanical properties when exposed to prolonged sunlight and harsh environmental conditions. This material is often chosen for projects requiring high-performance parts that must withstand the elements, such as automotive components, outdoor signage, or functional prototypes intended for outdoor use.

HIPS

High Impact Polystyrene (HIPS) derived from polystyrene and is recognized for its excellent impact resistance and ease of use. It is a lightweight material with good rigidity, making it suitable for prototyping. HIPS is known for its solubility in limonene, a non-toxic solvent, which makes it an ideal choice for creating complex support structures that can be easily dissolved, leaving behind a smooth, clean surface on the 3D printed object. This material is commonly used in applications where easy-to-remove supports and a balance between strength and weight are essential, such as in the production of intricate and detailed models or functional prototypes.

PA12

PA12 filament, or Nylon, is lauded for its resilience and adaptability in manufacturing. Derived from polyamide, it offers exceptional durability and flexibility. Lightweight yet robust, it’s perfect for intricate models and prototypes. PA12 is compatible with various post-processing techniques, enhancing both aesthetics and functionality. It boasts excellent resistance to heat and chemicals. PA12 can be dissolved using specific solvents for easy support removal. Engineers and designers value PA12 for its strength, versatility, and ease of use in diverse applications.

PC

Polycarbonate (PC) filament is a tough thermoplastic material favored in 3D printing for its exceptional strength, durability, and heat resistance, withstanding temperatures up to 150°C without deforming. Known for its optical clarity, PC filament is easily colored and resistant to chemicals. Despite its high printing temperature and tendency to warp, it’s widely used in manufacturing prototypes, automotive parts, electronic housings, and other demanding applications due to its unique combination of properties.

DLP technology

| Print area | 165 x 132 x 80 mm |

| Resolution | 0,035 mm |

| Light source | Parallel matrix (LED x 15) |

| Printing accuracy | 3,840 x 2,400 px (4K) |

| Available materials | Standard Resin, ABS-like Resin, Tough Resin, Clear Resin, Water-washable Resin |

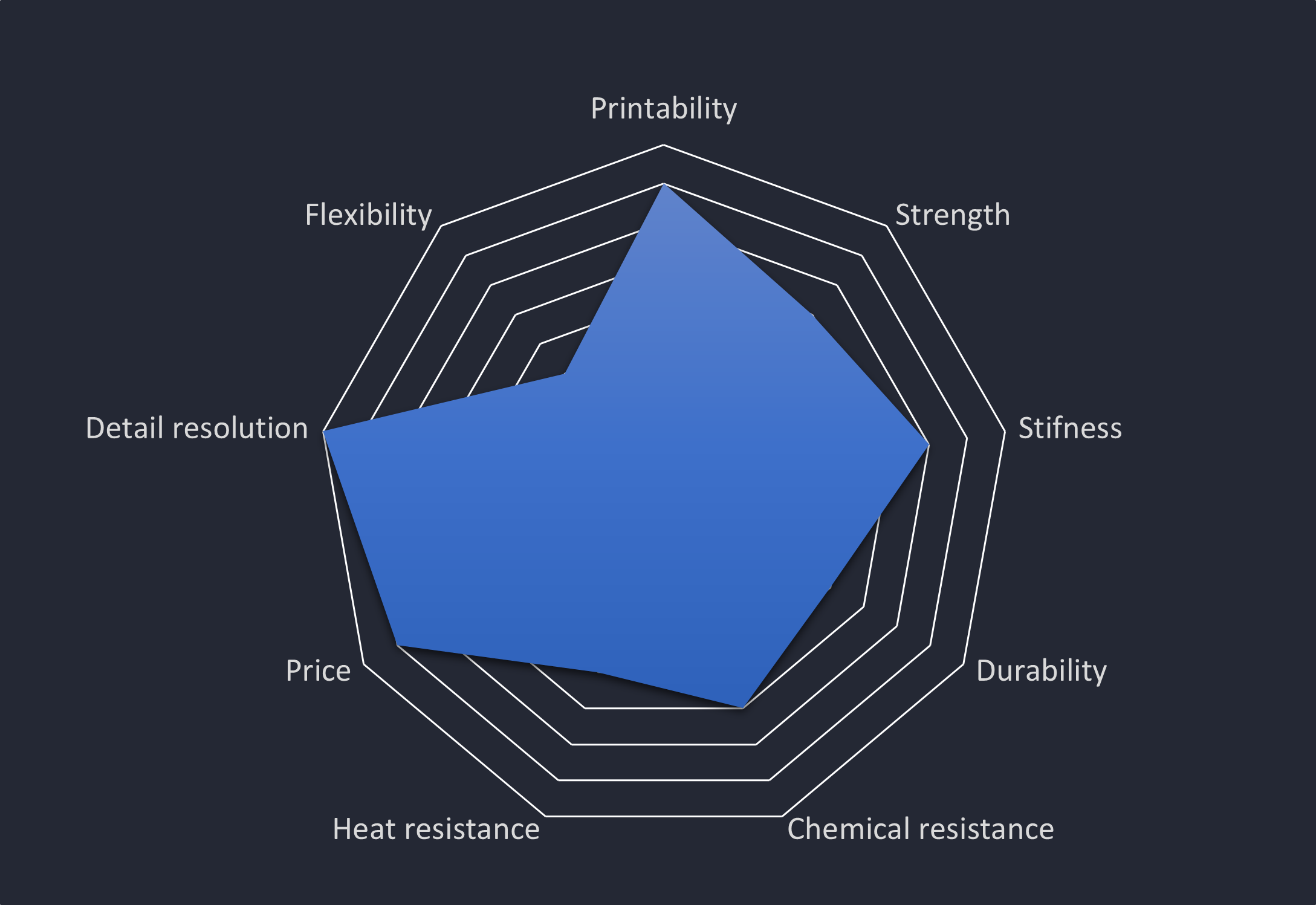

Standard Resin

Standard resin is a versatile photopolymer widely used in DLP 3D printing. It offers a balanced set of properties, making it suitable for a variety of applications. Known for its excellent detail resolution and smooth surface finish, standard resin excels in producing intricate models and prototypes. It cures quickly under UV light, allowing for faster print times. While it may not match specialized resins in specific properties, its affordability and ease of use make it a popular choice for both beginners and experienced users in fields such as jewelry design, dental applications, and miniature modeling.

ABS-like Resin

ABS-like resin is engineered to mimic the properties of ABS (Acrylonitrile Butadiene Styrene) plastic, offering enhanced durability and heat resistance compared to standard resins. This photopolymer is ideal for functional prototypes and end-use parts that require higher strength and impact resistance. It maintains good printability while providing improved mechanical properties, making it suitable for automotive parts, consumer goods prototypes, and industrial applications. ABS-like resin combines the detail capabilities of resin printing with the robustness typically associated with filament-based ABS prints, bridging the gap between aesthetic models and functional part

Tough Resin

Tough resin is specifically formulated to produce highly durable and impact-resistant parts. It excels in applications requiring flexibility combined with strength, resisting breakage and deformation under stress. This resin type is particularly useful for creating functional prototypes, engineering parts, and items that need to withstand repeated use or impact. Its enhanced durability makes it ideal for producing snap-fit assemblies, living hinges, and parts with thin walls. While it may require more post-processing and have a higher price point, tough resin is invaluable in industries such as automotive, aerospace, and consumer product development where part longevity and performance are crucial.

Clear Resin

Clear resin is designed for applications requiring transparency or translucency in 3D printed parts. It offers unparalleled detail resolution and surface finish, making it perfect for visual prototypes, artistic creations, and optical components. When properly post-cured and polished, clear resin can achieve a glass-like transparency, suitable for lenses, light pipes, and display models. While it may not match the strength of other specialized resins, its unique optical properties make it indispensable in fields such as product design, architecture, medical modeling, and artistic sculpture. Clear resin allows for the creation of complex internal structures that can be visually examined, adding a new dimension to prototype evaluation and artistic expression.

Water-washable Resin

Water washable resin is an innovative photopolymer designed to simplify the post-processing phase of DLP 3D printing. Its unique formulation allows printed parts to be cleaned with water instead of harsh solvents, making it safer for users and more environmentally friendly. This resin type offers excellent printability and good detail resolution, making it suitable for a wide range of applications, from hobbyist projects to professional prototyping. While it may not match the mechanical properties of specialized engineering resins, its ease of use and reduced environmental impact make it an attractive option for educational settings, home users, and businesses looking to minimize their use of chemicals. Water washable resin is particularly valued in industries where quick prototyping and minimal post-processing time are priorities, such as product design, architecture, and small-scale manufacturing.